J & K INDUSTRIES

11, Premsons Industrial Estate, Tahira Compound, Caves Road, Jogeshwari (East), Mumbai - 400060.

JK-ZH-140

ZERO-HALOGEN LOW SMOKE FLAME RETARDANT COMPOUND

PRODUCT DESCRIPTION:

JK-ZH-140 is a Zero Halogen Low Smoke, Flame Retardant & UV Stabilized Thermoplastic RoHS compliance Compound,

polyolefin based for Flexible Insulation Sheathing Compound for Power & Telecommunication cable.

SPECIFIC TION: IEC 60502-1 STB VDE 0207 Pt.24 HM2 & HM4 IEC 60332-1/2

JK-ZH-140 provides following properties

• Good abrasion resistance

• Excellent mechanical properties

• Long-term reliability & UV stability

• Excellent flame retardancy & low smoke

• Smooth Finish

KEY FE TURE:

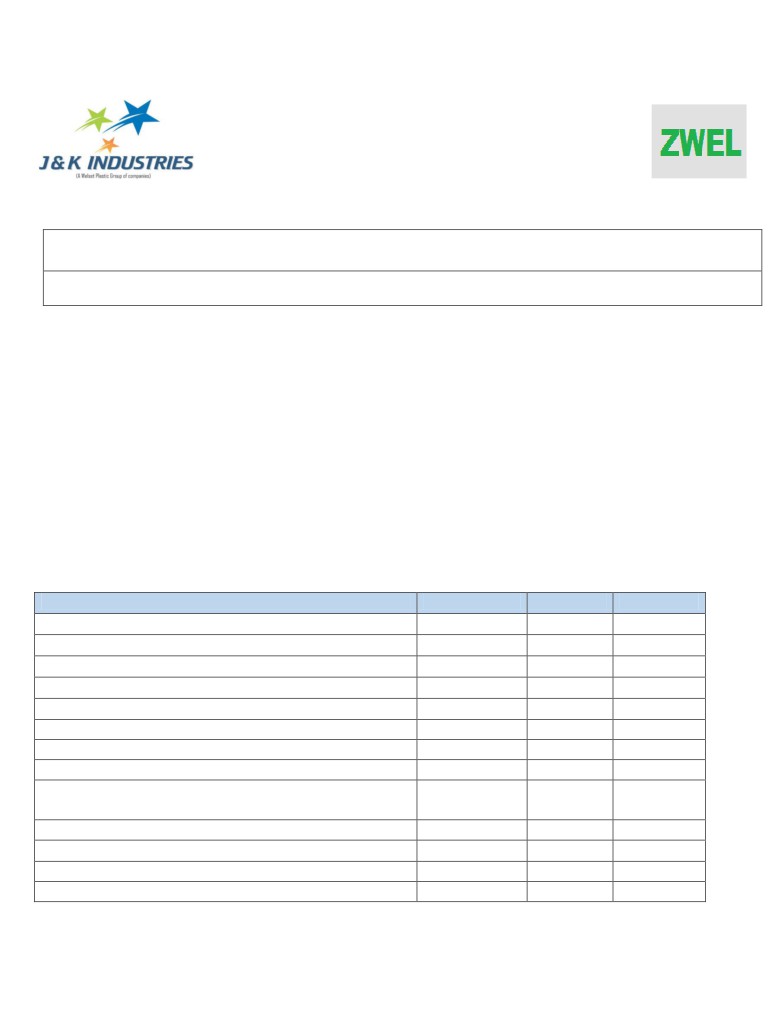

Properties

Test Method

Units

Value*

Colour

Natural

Natural

Natural

Shape

Cylindrical

Cylindrical

Cylindrical

Size

3mm

3mm

3mm

Melt Index @ 21.6 Kg. 160°C

ASTM D 1238

gm/10 min

11.5

Density

ASTM D 792

gm/cc

1.47

Tensile Strength

ASTM D 638

N/mm²

12

Elongation

ASTM D 638

%

200

Smoke Density Rating

ASTM D 2843

%

4

Variation of Tensile Properties after Heat Ageing

at 100±2°C for 168 Hrs.

% Variation TS

ASTM D 638

%

+ 5

% Variation EL

ASTM D 638

%

- 18

Hardness

ASTM D 2240

Shore ‘D’

49

Limiting Oxygen Index

ASTM D 2863

% O²

33

Processing Parameters:

JK-ZH-140 range of compounds are designed to perform on extruder with Low

compression ratio screws meant for PE extrusion. However it can also be used

on PVC extruder with limitation on output. The recommended temperature for

extruding JK-ZH-140 compound is in the range of 115°C to 145°C for barrel and

150°C for cross head and die. Extra caution must be exerted to see that the

processing temperature does not exceed 175°C which will result in

degradation of the material. Pre-drying of the compound is recommended at

70°C for 2 hours to obtain smooth processing of the cable and attaining good

surface finish on the cable.

Colorability

JK-ZH-140 is a Colorable Compound with PE/EVA base master batch.

Packaging & Storage:

JK-ZH-140 compounds are free flowing pallets and are packed in securely

sealed laminated PP bags with liner to protect against moisture.

The standard packing is 25 kg per bag.

It is recommended to store the material away from direct sunlight and cool

and dry place.

Shelf Life:

Shelf Life of the compound is 12 months from the date of manufacture.

Product alteration may occur due to extended period of storage

Technical Assistance:

Our experienced technical team will be available for assistance on request.

11, Premsons Industrial Estate, Tahira Compound, Caves Road, Jogeshwari (East), Mumbai - 400060.

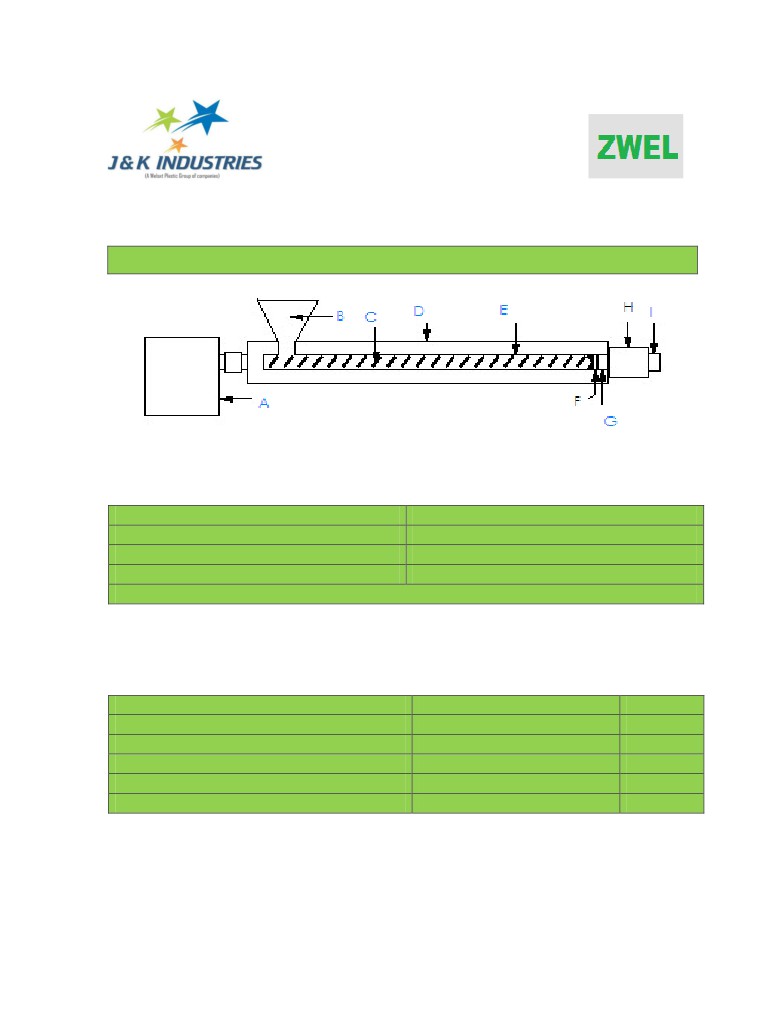

EXTRUSION PROCESSING GUIDE

[LOW COMPRESSION RATIO SCREW]

A - Drive

F- Screen Box

B -Feed

G - Breaker Plate

C - Screw

H - Die Body

D - Barrel Heater Zones

I - Die Head

E - Barrel Liner

TEMPERATURE SETTINGS

Extrusion

Nominal Value

Unit

Cylinder Zone 1 Temp.

115 ± 5

°C

Cylinder Zone 2-3 Temp.

120 ± 5

°C

Cylinder Zone 4-5 Temp.

130 ± 5

°C

Melt Temperature

140 ± 5

°C

Die Temperature

145 ± 5

°C

11, Premsons Industrial Estate, Tahira Compound, Caves Road, Jogeshwari (East), Mumbai - 400060.